Hoping that your extract will pair seamlessly with cookie-cutter vape hardware is an exercise in futility. Like fingerprints or snowflakes, no two extracts are exactly the same. They have different viscosities, distinct flavour profiles and unique terpene/cannabinoid compositions. To get the most out of your extract, you can’t just select out-of-the-box vape hardware with a good reputation. You need to find the hardware that best suits your formulation.

Although this concept seems like a no-brainer, the nascency of the cannabis vape sector precluded it from being a realistic possibility until only quite recently. After all, it was less than a decade ago that portable cannabis vape hardware first entered the market in the form of plastic cartridges and wicks. These devices may have been revolutionary at the time, but their heating cores and saturation systems were predicated on e-cigarette technology and could not adequately handle the thicker viscosities of cannabis oil. The result was devices that regularly leaked, clogged and produced inconsistent, flavorless and often burnt vapour. In short order, glass cartridges were introduced to the market and quickly became the industry standard. Coil technology also underwent a rapid transformation, with quartz wicks overtaking plastic wicks for a brief period of time before ultimately making way to ceramic heating cores.

The evolution of portable cannabis vape technology is far from complete; the sky is truly the limit for this pursuit and it will be fascinating to see how hardware continues to evolve over the next 10-20 years. Since 2020, the industry has shifted its focus from reinventing the engine and the frame to ensuring the hardware under the hood functions no matter the fuel. To cater to the myriad extract properties and viscosities currently on the market, hardware-solutions providers are now offering more standard options at the spec level than ever before.

APERTURE SIZE OPTIONS

Accurately pairing extracts with suitable vape hardware starts with selecting the correct aperture size. Also known as intake or inlet holes, these openings in the centerpost act as gateways, limiting the rate at which the extract flows into the chamber and saturates the heating core. If the apertures in your hardware are too large, your extract could oversaturate the heating core, seep into the centerpost, and potentially leak out of the mouthpiece. If the apertures in your hardware are too small, your extract could struggle to permeate the chamber, producing little to no vapor at all. Neither are ideal.

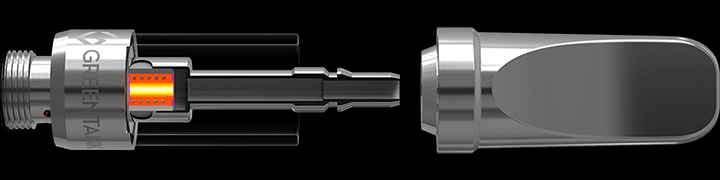

To counter these issues and cater to a wider range of extract viscosities, manufacturers are now offering multiple aperture size options for the same product SKUs. Greentank, for instance, offers five aperture size options for its flagship GT CR cartridge: 1.0 mm, 1.2 mm, 1.5 mm, 1.8 mm and 2.0 mm. Manufacturing capabilities have even advanced to the point that some hardware providers are now offering brands the opportunity to request precise aperture hole sizes to the millimetre that fit the specific viscosities of their extracts like gloves.

UNIQUE PROPRIETARY CERAMIC CORES

As we mentioned earlier, ceramic cores have become the industry standard for several reasons: they are oxidation and heat-resistant, saturate quicker and retain heat more efficiently than traditional wick systems, prevent burning, and provide the most consistent and flavourful vapor of any heating element type on the market. But not all ceramic cores are the same, or equal.

Proprietary ceramic cores can differ significantly from one manufacturer to another in terms of ceramic qualities, porosities, heat-resistances and airflow designs. These differences may seem minimal on the surface but in reality they determine how efficiently your device heats and saturates your extract, how consistent the vapour production is, how functionally it operates in more extreme climates and conditions, and how resistant it is to leaching and deterioration.

Simply put, choosing the correct ceramic core for your extract is crucial to your product’s success.

BATTERY FEATURES

Batteries are the beating hearts of vaporizers as they supply the charges needed to transform extracts into flavourful vapor. Selecting the battery that will best optimize the idiosyncrasies of your extract is critical, but it’s no easy task due to the sheer number of different battery options currently in the market.

Manufacturers are offering more battery options and voltage outputs than ever before to both optimize the extracts housed in their hardware and provide end-users with vaping experiences that would have been inconceivable just a few years ago. Brands can now opt for batteries that offer pre-heating options, variable heat settings, push-button or breath-actuated activation, recharging capabilities, and a variety of cycle capacities to best fit the needs of their extracts and consumer bases. They also have the opportunity to select the form factors and tube materials that best gel with their brands’ aesthetics and personalities.

CUSTOMIZATION CAPABILITIES

Selecting hardware that elevates your extract is paramount, but the importance of ensuring that your hardware solutions provider has the customization capabilities your brand requires cannot be understated.

Device customization and branding (e.g. unique mouthpiece options, surface finishes, secondary treatments) are crucial components of making your product stand out on retail shelves. Unfortunately, not all vape hardware-solutions providers possess the same customization capabilities. Some offer only a few basic mouthpieces and surface customizations for each SKU; others, like Greentank, provide their partners with dozens of compatible mouthpiece options and comprehensive catalogues of finishes and treatments that include more refined application techniques, such as anodization, pearlescent coating, ultra-high gloss painting, laser etching and immersion printing.

PRODUCT SAFETY, TESTING AND COMPLIANCE

“Strict additional industry regulations can be difficult for smaller hardware manufacturers to overcome, but they create the types of evolutionary bottlenecks that challenge businesses to innovate. We see them as opportunities to demonstrate our commitment to quality and innovation.” – Pete Duckett (Chief Engineer, Greentank)

Product safety and regulatory compliance have rapidly moved to the forefront of the cannabis vape space in the aftermath of last year’s black market vape cartridge crisis. Consumers, understandably, want to know every detail about what they’re inhaling, from complete lists of materials and ingredients to all applicable testing results.

For vape hardware providers, total transparency means supplying partners with material safety data sheets, heavy metal and child-resistance testing results, product and factory safety certifications, and a detailed accounting of manufacturing safety and quality-control protocols. It also means being able to supply any requested materials that confirm the compliances of certain aspects of their hardware with specific jurisdictional regulations.

In a perfect world, every hardware provider would be able to supply all of the safety materials listed above. In reality, though, that simply isn’t the case. Some hardware providers do not prioritize transparency and user safety above all else, and you simply cannot afford to tie the success of your extract to businesses that do not offer this entire suite of documentation.